Features of the Integrated Coal Gasification Combined Cycle (IGCC) Technology

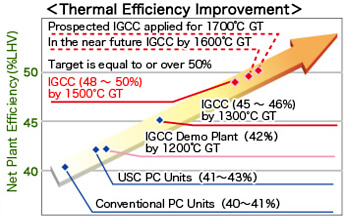

Advantage 1 Improved Power Generation Efficiency and Solution to Global Warming

Gasification of coal (solid fuel) allows the combined use of steam and gas turbines, creating the potential to increase estimated power generation efficiency to 48% to 50% (for an IGCC system) in commercial applications, compared to levels of approximately 42% for conventional coal-fired power generation systems.

The foregoing advantage may well lead to coal-based power generation at CO2 emission rates more or less equal to oil based power generation.

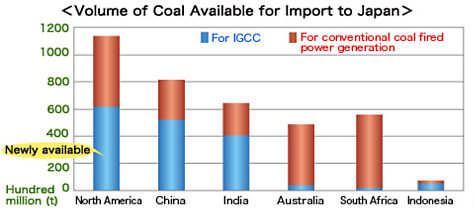

Advantage 2 Wider Choice of Applicable Coal Types

The technology takes advantage of coal, the most abundant of natural resources. The technology can also be used with coal types that have low ash melting temperatures, materials that do not readily lend themselves to use for conventional coal-fired power generation. In this way, the technology may pave the way for a wider choice of usable coal types for Japan.

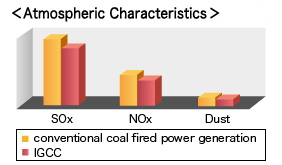

Advantage 3 Atmospheric Environmental performance.

With IGCC, the gasification of coal (solid fuel) enables power generation through a combination of steam and gas turbines, resulting in projected power generation efficiency rates of 48% to 50% in commercial applications, compared to levels of approximately 42% rate for conventional coal fired power generation.

The higher efficiency of the systems will reduce SOx, NOx, and dust emission per unit of electricity generated (kWh).

Advantage 4 Effective Use of Slag

Conventional coal-fired power generation produces large volumes of coal ash. IGCC discharges it in the form of glassy slag, cutting volumes of this waste product by nearly half.

This slag can be recycled for other uses, including cement components and road materials.

Advantage 5 Other Features

Reduced Cooling Water

Designed as a combined cycle power generation system using a gas turbine, IGCC can reduce cooling water by roughly 30% compared to conventional coal-fired power generation methods.

Reduced Service Water Usage

The flue gas desulfurization equipment used in conventional coal-fired power generation treats emissions(SOx,NOx,Dust) in the exhaust gas phase subsequent to burning of the fuel, an approach that inherently requires large volumes of water. IGCC deals with the emissions during the fuel gas phase, significantly reducing the amount of service water needed.