Demonstration test results

Particulars and Results of Demonstration Testing (Overview)

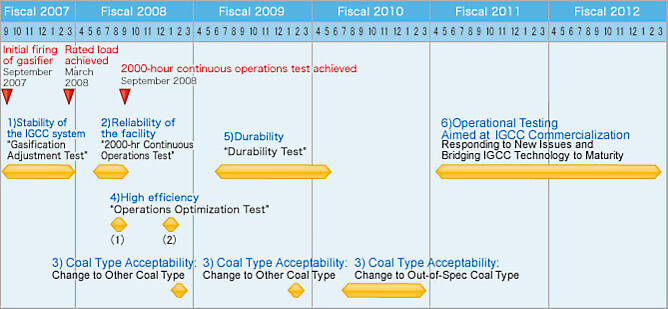

IGCC demonstration tests were conducted over a period of about 3 years and 7 months, starting with ignition of the gasifier in September 2007, and continuing up to March 2011. The test was conducted according to the schedule shown below. In general, all of the initial targets were achieved.

Further tests are planned for the next two years, from fiscal 2011 through the end of fiscal 2012, to (a) respond to new issues that have arisen, and to (b) aim at continuing maturation of IGCC technology, focusing on reliability, economic feasibility, and coal-type adaptability. Our underlying plan is to tie these efforts into the smooth commercialization of these systems.

Demonstration Test Schedule

Verification Items and Particulars of Demonstration Testing

| Item | Goal |

|---|---|

| 1) System Safety and Stability |

Demonstrate safe shutdown when plant malfunctions, and safe handling of coal gas. |

| 2) Reliability | Run continuously for at least 2000 hours (equivalent to 3 summer months) to confirm reliability. |

| 3) Coal Type Flexibility |

Collect data while running coal types outside of the design specs. Data is to be used to support future commercial design. |

| 4) High Efficiency | Achieve targeted thermal efficiency, to show that system delivers the high efficiency that is said to be IGCC’s greatest advantage. |

| 5) Durability | Run for long period, then conduct overhaul inspection to demonstrate durability. |

| 6) Economy | Use operational performance as a basis for comprehensive evaluation of costs (construction costs, operating costs, maintenance costs etc.), and evaluate economic feasibility. |

1) System Safety and Stability

| Verification Items (Overview) |

Results of Demonstration Testing (Overview) |

Evaluation |

|---|---|---|

| ・Safe shutdown when plant malfunctions. |

・Simulated a malfunction and tested interlocks to confirm safe plant shutdown. |

Confirmed that system is stable.Objective accomplished |

| ・Safe handling of coal gas. | ・Ran various trials and adjustments, and confirmed that gas handling is always safe and that there are no operational errors. ・Confirmed system stability by demonstrating stable continuous operation at rated load (250 MW). |

2) Reliability of the Facility

| Verification Items (Overview) |

Results of Demonstration Testing (Overview) |

Evaluation |

|---|---|---|

| ・Run continuously for 2000 hours. (Equivalent to 3 months of summer.) | ・Confirmed stable operation over 2039 consecutive hours. | Achieved continuous-run target. Going forward, will also check durability over mid-to-long-term continuous operation.Objective accomplished |

3) Coal Type Flexibility

| Verification Items (Overview) |

Results of Demonstration Testing (Overview) |

Evaluation |

|---|---|---|

| ・Collect data while running on coal types outside of the design specs. | ・Operated plant on three different types of sub-bituminous coal, and collected operational data. ・In some cases, coal characteristics caused blockage in heat-transfer piping in the heat exchanger (SGC) downstream of the gasifier. |

Analyzed operation when using three coal types outside the range of the design specs, collecting data to be used to support future design of commercial-level facilities. In some cases, blockage occurred in the SGC heat-transfer piping downstream of the gasifier. Results made it clear that various countermeasures would be needed to prevent problems caused by different coal types. Objective accomplished |

4) High Efficiency

| Verification Items (Overview) |

Results of Demonstration Testing (Overview) |

Evaluation |

|---|---|---|

| ・Targeted thermal efficiency (Achieve LHV 42% LHV at sending end) | ・Achieved 42.9% LHV at sending end. | Demonstrated high efficiency.Objective accomplished |

5) Durability

| Verification Items (Overview) |

Results of Demonstration Testing (Overview) |

Evaluation |

|---|---|---|

| ・Run for long period, then do overhaul inspection to evaluate durability. | ・Ran 5000 hours in one year. •After running 5000 hours, conducted overhaul inspection. Confirmed that there were no critical device faults. |

Confirmed that the tested equipment has an appropriate IGCC design. Going forward, will also check durability over mid-to-long-term continuous operation.Objective accomplished |

6) Economy

| Verification Items (Overview) |

Results of Demonstration Testing (Overview) |

Evaluation |

|---|---|---|

| ・Evaluate economic feasibility based on operational performance. | ・While it seems that gasified-coal systems will have higher construction and repair costs. relative to pulverized-coal systems, we expect that they will also deliver better thermal efficiency and low fuel costs. | Based on the results, it seems quite possible that gasified coal may deliver power-generating costs equal to or lower than those for pulverized coal. Yet, it will be required to enhance precision of these systems for lower repair costs.Objective accomplished |

See more detailed test results here.

New verification items and their contents

1) Reliability

| Verification Items (Overview) |

Results of Demonstration Testing (Overview) |

Evaluation |

|---|---|---|

| ・Confirm the mid-to-long term durability of the IGCC facilities including countermeasures implemented during the past testing. | ・Countermeasures to initial stage troubles were worked well in 2011. ・Additional two countermeasures to mid-and-long term troubles were implemented. |

・Countermeasures to initial troubles were identified as effective and durable. ・Countermeasures to latest troubles were also established and effectiveness was checked.Objective accomplished |

| ・Durability of countermeasures was confirmed in 2012. ・Two countermeasures against troubles caused by long-term effects are implemented and their effectiveness was checked in the end of fiscal 2012. |

2) Coal Type Flexibility

| Verification Items (Overview) |

Results of Demonstration Testing (Overview) |

Evaluation |

|---|---|---|

| ・Establish the measures against the troubles accompanied by use of some coal types. | ・Another types of bituminous, Columbian Russian and Indonesian coals were in use and operational data were collected in 2011. ・Some coal type brought about clogging in SGC heat exchanger piping facility. |

・5 types of coal except for designed coal were applied and operational parameters adjustment was performed, which realized optimal operation in each coal type. ・Countermeasures with design and proper operation against clogging in Heat exchanger piping facility were confirmed to be effective.Objective accomplished |

| ・Another types of sub-bituminous (USA)and bituminous(Canada) coals were tested in 2012. ・Countermeasures against SGC clogging such as design improvement in SGC heat exchanger pipe facility design and operation were confirmed to be effective. |

3) Economy

| Verification Items (Overview) |

Results of Demonstration Testing (Overview) |

Evaluation |

|---|---|---|

| ・Increase in samples of maintenance and inspection results for analyzing the maintenance cost which should be compatible with conventional pulverized coal fired generation. | ・Design improvement in SGC Heat exchanger was developed in 2011. ・Prolongation of inspection period was studied. |

・It was confirmed that design improvement in SGC Heat exchanger brought about no problem and was effective measure to reduce the SGC volume. ・Appropriate period and contents for maintenance inspection were more precisely identified.Objective accomplished |

| ・Design improvement in SGC Heat exchange was partially installed and no trouble was observed in 2012. ・Prolongation of inspection period was studied. |