Integrated Coal Gasification Combined Cycle (IGCC)

The firing of the gasifier on September 20, 2007, marked the completion of IGCC demonstration plant construction and the start of demonstration test.

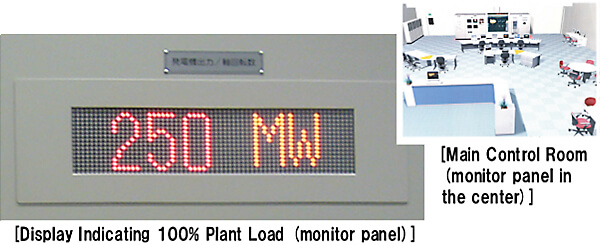

Coal gas was first introduced into the gas turbine in early December 2007. A plant load of 50% was achieved toward the end of the same month. Test progressed steadily until the plant achieved a load of 75% in early January 2008 and, ultimately, 100% (250 MW) on March 7 of the same year. (See the photo below.)

The status of individual systems and equipment during fiscal 2007 is given below:

(1) Gasification system

| [September] | After the firing of the gasifier on September 20, the temperature and pressure of the gasifier were raised while burning kerosene fuel to confirm safety with kerosene gas before introducing coal into the gasifier. (The gasifer temperature must be raised to a certain point with kerosene to activate gasification of coal.) |

| [October] | Test also included the switch from kerosene to coal for the gasifier. This confirmed that the operating conditions of the gasifier and the mode of slag discharge were consistent with design. |

| [November] | Tests confirmed that the gasifier could be controlled as designed. |

| [December through March] | The tests performed during these months involved varying the pressure of the coal gas to confirm satisfactory controllability.The gasifier and the gas turbine were also operated under coordinated control to confirm operational stability. |

(2) Gas cleanup system

| [September] | Combusted gas originated from the kerosene in the gasifier was supplied through the gas clean up system. |

| [October] | Feeding of coal gas began in the middle of the month. Amine regeneration (amine being the chemical solvent used in the gas cleanup process) began toward the end of the month. |

| [November] | The operation of the off-gas incinerator used to burn the sulfur components recovered from coal gas was studied to confirm combustion status. The sulfur recovery system was then adjusted. The results were positive. |

| [December through March] | The stability of coal gas system operations was confirmed under various load conditions. |

(3) Combined Cycle Power Generation System

| [September] | General interlock test was performed by operating the gas turbine at 25% load (kerosene-fired). |

| [October] | The operating parameter of the system was adjusted during the on-load operation. |

| [November] |

In mid-month, the turbine was abruptly stopped to test various operational aspects. A good result was obtained during the test. Toward the end of the month, the fuel gas pipe was purged to confirm various aspects of this procedure. (Purging involved displacing air inside the fuel pipe with nitrogen before introducing coal gas into the gas turbine.) |

| [December through March] |

Tests to confirm problem-free fuel switching (kerosene ←→coal gas) for the gas turbine were combined with tests of combustion under various load conditions. General interlock test performed for coal gas-firing confirmed that individual systems could be shut down safely. |

Integrated coal gasification combined cycle(IGCC)

Clean Coal Power R&D Co., Ltd. conducted IGCC demonstration test from 2007 to the end of fiscal 2012.Joban Joint Power Co., Ltd.. took over the demonstration plant as Nakoso power station unit No. 10 for commercial operation from fiscal 2013.

Air blown type IGCC system is adopted for unit No. 10.

In 2013, commercial operation of unit No.10 had started from June 28th and it stopped December 8th.

The operation time was 3,917 hours. It broke the world record for continuous operation time(3,287 hours) of IGCC which was set by Bugghenum power station in Netherland.

Unit No.10 has been discontinued.

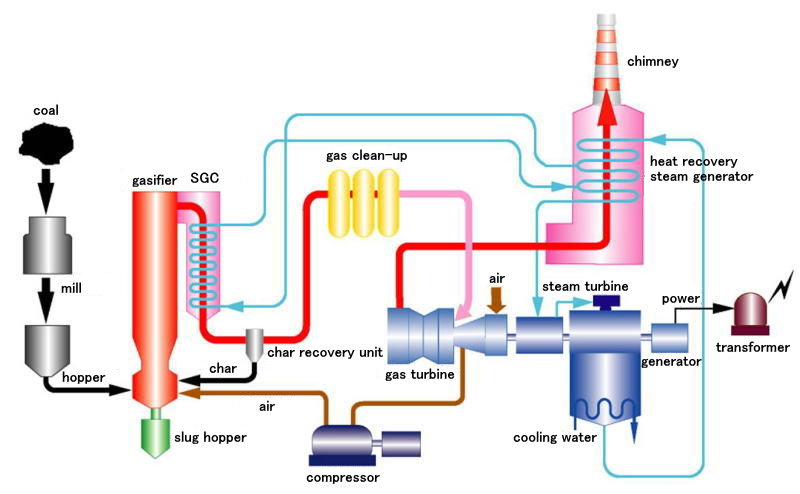

Schematic of IGCC

An IGCC system is designed to achieve higher efficiency than conventional coal-fired power generation systems through the gasification of coal coupled with a combined cycle (CC) process.

Specifications of No.10 unit

| Capacity | 250 MW gross | |

|---|---|---|

| Coal Consumption | approx. 1,700 metric t/day | |

| System | Gasifier | Air-blown & Dry Feed |

| Gas Treatment | Wet (MDEA) + Gypsum Recovery | |

| Gas Turbine | 1200 deg C-class (50Hz) | |

| Efficiency (Target Values) |

Gross | 48% (LHV) 46% (HHV) |

| Net | 42% (LHV) 40.5% (HHV) | |

A number of IGCC projects are currently being pursued worldwide.

Preceding IGCC

| Project name Operating company (Country) |

Gasifier (Blown type) |

GT | Gross Output (MW) |

Commercial Operation month-year |

Consecutive Operation (hours)* |

Remark |

|---|---|---|---|---|---|---|

| Buggenum Nuon(Vattenfall) (Netherland) |

Shell (O2) |

Siemens V94.2 |

284 | Jan-94 | 3,287 | |

| Wabash River Wabash Valley Power (USA(Indiana)) |

E-Gas (Dow) (O2) |

GE 7FA |

296 | Aug-95 | 1,848 | |

| Polk Power Tampa Electric (USA(Florida)) |

GE (Texaco) (O2) |

GE 7FA |

315 | Jul-96 | 1,673 | |

| Puertollano ELCOGAS (Spain) |

Prenflo (O2) |

Siemens V94.3 |

318 | Nov-97 | 954 | |

| IGCC demonstration plant CCP (Japan(Fukushima)) |

MHI (Air) |

MHI 701DA |

250 | Jul-13 | 3,917 | Commercial operation a unit No.10 began in April,2013 |

*using only syngas

Year-by-Year Demo Test Status

Results of Demonstration Testing (Detailed)

1) IGCC System Stability: “Coal Gasification Adjustment Testing”

| Verification Items (Overview) |

Demo Test | Results of Demonstration Testing |

Evaluation |

|---|---|---|---|

| ・Stable shutdown when plant malfunctions. |

Test the interlocks to confirm safe plant shutdown. Test period: FY 2007 |

|

Confirmed that system is stable.Objective accomplished |

| ・Safe handling of coal gas. |

Check and adjust plant operating status, and confirm that coal gas is handled safely and that operation is stable under rated load.

|

|

2) Reliability of the facility: “2000-hours sustained operation”

| Verification Items (Overview) |

Demo Test | Results of Demonstration Testing |

Evaluation |

|---|---|---|---|

| ・Running continuously for 2000 hours (equivalent to 3 months of summer). |

Run continuously for 2000 hours.

|

|

Achieved continuous-run target. Going forward, will also check durability over mid-to-long-term continuous operation.Objective accomplished |

3) Coal Type Acceptability: Change to Other Coal Type / Change to Out-of-Spec Coal Type

| Verification Items (Overview) |

Demo Test | Results of Demonstration Testing |

Evaluation |

|---|---|---|---|

| ・Collecting data while running on coal types outside of the design specs. |

Check operation when using sub-bituminous coal (North American, Indonesian A).

|

|

Analyzed operation when using three coal types outside the range of the design specs, collecting data to be used to support design of commercial-level facilities. In some cases, SGC heat-transfer piping downstream of the gasifier became clogged. Results made it clear that various countermeasures would be required to prevent problems caused by different coal types. Objective accomplished |

|

Check operation when using sub-bituminous coal (North American).

|

|

||

|

Run plant with the purpose of enabling use of mainstream coal types beyond those covered by the design specs, and of sub-bituminous types capable of single-fuel firing.

|

|

4) High Efficiency: “Operations Optimization Test”

| Verification Items (Overview) |

Demo Test | Results of Demonstration Testing |

Evaluation |

|---|---|---|---|

|

Verify efficiency; investigate whether reasonable to anticipate efficiency enhancements sufficient for commercial use.

|

By adjusting running parameters, able to confirm an LHV of 42.9% at the sending side, surpassing the goal of 42% LHV. | Confirmed high efficiency.Objective accomplished |

5) Durability : “Durability Confirmation Test”

| Verification Items (Overview) |

Demo Test | Results of Demonstration Testing |

Evaluation |

|---|---|---|---|

|

Run for 5000 hours, then did overhaul inspection to evaluate durability.

|

|

Confirmed that the tested equipment has an appropriate IGCC design. Going forward, will also check durability over mid-to-long-term continuous operation. Objective accomplished |

6) Economy: “Assessment of Cost-Effectiveness”

| Verification Items (Overview) |

Demo Test | Results of Demonstration Testing |

Evaluation |

|---|---|---|---|

|

Used operational performance as a basis for comprehensive evaluation of costs (construction costs, operating costs, maintenance costs, etc.); and evaluated whether this approach would be economically feasible in a commercial environment.

|

|

Based on the results, it seems quite possible that gasified coal may deliver power-generating costs equal to or lower than those for pulverized coal. But will need to enhance precision of these systems for lower repair costs.Objective accomplished |

New verification items and their contents

1) Reliability

| Verification Items (Overview) |

Demo Test | Results of Demonstration Testing |

Evaluation |

|---|---|---|---|

|

These studies as follow conducted. ・Durability assessment on the countermeasures against the troubles in the past. .

Test period: FY 2011 |

|

・Countermeasures to initial stage troubles were basically effective in long-term perspective such as durability. ・Latest troubles were analyzed and effective countermeasures were established, which were inspected in the maintenance work afterward and no trouble was identified. Objective accomplished |

|

Confirm the mid-to-long term durability with further operation duration.

|

|

2) Coal Type Flexibility

| Verification Items (Overview) |

Demo Test | Results of Demonstration Testing |

Evaluation |

|---|---|---|---|

|

Other types of bituminous coal except for design coal, that is, Columbian, Russian and Indonesian coals are to be in use and operational data to be collected in 2011.

|

|

・5 types of coal except for design coal was identified as applicable by the original and optimal adjustment in each coal type. ・Countermeasures newly developed in the design and its operation against clogging in SGC heat exchanger facility was identified as effective. Objective accomplished |

|

Another types of bituminous coal(USA) and sub-bituminous coal (Canada) were tested in 2012. Test period: FY 2012 |

|

3) Economy

| Verification Items (Overview) |

Demo Test | Results of Demonstration Testing |

Evaluation |

|---|---|---|---|

|

Study on the cost reduction methods at commercial stage reflecting the operation and maintenance results in 2011. Test period: FY 2011 |

|

・The design improvement In SGC was confirmed to be effective to reduce the SGC volume. ・Inspection period in each IGCC part was more precisely identified through the experience on the maintenance work, operation and facility troubles. Objective accomplished |

|

Cost reduction measures were further conducted, reflecting the operation and maintenance experiences in 2012. Test period: FY 2012 |

|