Annual brief overview

Fiscal 2007 Status of Demonstration Test

The firing of the gasifier on September 20, 2007, marked the completion of IGCC demonstration plant construction and the start of demonstration test.

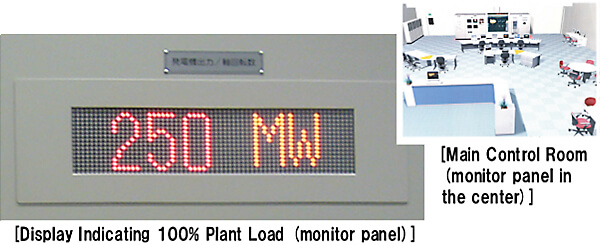

Coal gas was first introduced into the gas turbine in early December 2007. A plant load of 50% was achieved toward the end of the same month. Test progressed steadily until the plant achieved a load of 75% in early January 2008 and, ultimately, 100% (250 MW) on March 7 of the same year. (See the photo below.)

The status of individual systems and equipment during fiscal 2007 is given below:

(1) Gasification system

| [September] | After the firing of the gasifier on September 20, the temperature and pressure of the gasifier were raised while burning kerosene fuel to confirm safety with kerosene gas before introducing coal into the gasifier. (The gasifer temperature must be raised to a certain point with kerosene to activate gasification of coal.) |

| [October] | Test also included the switch from kerosene to coal for the gasifier. This confirmed that the operating conditions of the gasifier and the mode of slag discharge were consistent with design. |

| [November] | Tests confirmed that the gasifier could be controlled as designed. |

| [December through March] | The tests performed during these months involved varying the pressure of the coal gas to confirm satisfactory controllability.The gasifier and the gas turbine were also operated under coordinated control to confirm operational stability. |

(2) Gas cleanup system

| [September] | Combusted gas originated from the kerosene in the gasifier was supplied through the gas clean up system. |

| [October] | Feeding of coal gas began in the middle of the month. Amine regeneration (amine being the chemical solvent used in the gas cleanup process) began toward the end of the month. |

| [November] | The operation of the off-gas incinerator used to burn the sulfur components recovered from coal gas was studied to confirm combustion status. The sulfur recovery system was then adjusted. The results were positive. |

| [December through March] | The stability of coal gas system operations was confirmed under various load conditions. |

(3) Combined Cycle Power Generation System

| [September] | General interlock test was performed by operating the gas turbine at 25% load (kerosene-fired). |

| [October] | The operating parameter of the system was adjusted during the on-load operation. |

| [November] |

In mid-month, the turbine was abruptly stopped to test various operational aspects. A good result was obtained during the test. Toward the end of the month, the fuel gas pipe was purged to confirm various aspects of this procedure. (Purging involved displacing air inside the fuel pipe with nitrogen before introducing coal gas into the gas turbine.) |

| [December through March] |

Tests to confirm problem-free fuel switching (kerosene ←→coal gas) for the gas turbine were combined with tests of combustion under various load conditions. General interlock test performed for coal gas-firing confirmed that individual systems could be shut down safely. |